WEBINAR EXECUTIVE SUMMARY:

How to Approach China Alternatives: Mexico, Southeast Asia & Central Eastern Europe

East West experts Mark Plum and Dan McLeod discuss how companies can approach finding alternatives to China for their manufacturing and supply chains, providing examples of companies they assisted diversifying from China while answering questions from the audience.

As manufacturing for export and sourcing in China is becoming more difficult for Western companies due to cost of inflation going up, increasing labor costs, high production expenses, volatile tariffs, political tensions, not to mention new and challenging rules and regulations that continue to evolve – companies are looking for other locations.

These trends are applicable to companies who are operating on the ground in China facilities and relocating them outside or sourcing them out of China for components or raw materials.

The questions to ask when looking to relocate are these:

-

- Where is your market?

- Where are your components and finished goods?

- Where are they to be consumed?

These three questions will help determine the best solution for your operations.

Attractive alternatives exist for relocating China supply chain & operations, including Mexico, Southeast Asia, and Central/Eastern Europe.

Client Case Study #1

Moving Operations to Mexico, Client is in US and North America

The first example was a very successful US-based manufacturer of electronic equipment selling into industrial markets and was established in China since the early 2000s. In addition to manufacturing, they had developed a sourcing office there, and they were sourcing components for their US factories. They had a strong operation with a strong domestic market, growing steadily, and were satisfied with the performance of their operations.

We were engaged a few years ago to initiate a search for suppliers in Mexico after the introduction of the tariffs in China. They also experienced logistics challenges, increased cost and transit times, problems with container availability, along with becoming increasingly concerned about the political situation between China and the US.

The company was looking forward into the future and had some concerns, particularly where their marketplace was somewhat of a high-tech product, were concerned about China’s 2025 policies and the potential for the loss of intellectual property and the loss of control of production.

We provided the company with options for suppliers Mexico to be closer to their clients in the US and North America and visited the top candidates.

Currently, in Mexico, we are finding:

-

- Suppliers are fielding more requests than the previous 5-10 years. This is stressing capacity and their ability to respond. Having good relationships with suppliers in Mexico is key to getting their attention, and having local people able to facilitate these relationships is critical.

- Finding local individuals who can support your negotiations, particularly around freight and logistics, standard terms and conditions, and trade compliance issues is important.

- For companies that move to Mexico, they can reduce the number of distribution centers they operate in North America since they’ve shortened their supply times by getting closer to the market and have a quicker response time. This also can reduce their inventory holdings.

- Incentives are not as transparent as other parts of the world – and more time and investment can be required. There is much more raw, undeveloped land on the market that requires more investment in time and capital to get set up as a manufacturing site.

- Many more small-to-medium sized suppliers, where capital is tight and when faced with the need to expand to supply a significant customer, there are discussions about financing the expansion, unlike you would with a supplier in China for example.

- When transferring technology to Mexico, it requires more work to develop the specifications and techniques than expected, which can slow the transition process down. This creates a requirement for technical skills within your company to help the transition.

Client Case Study #2

Moving Operations to Poland and Czech Republic, Clients are in Western Europe

Our next example was US global HVAC business, with manufacturing in the Guangzhou province in the 90s. Back then they were able to reduce their bill material cost and total cost between 25-30%. They could have long shipping lead times of 9-11 weeks to get to their different global distribution centers.

We were engaged to look at a new facility to help move it closer to their European markets to ease the shipping times to those markets. We determined the best area was along the Polish and Czech Republic boarder to get their goods into Western Europe, bringing the shipping times down to 10 hours by highway with a strong labor force in place.

Currently, in Eastern Europe, we find:

-

- Excellent suppliers for metal fabrication – bending metals, heavy construction, is extremely good, with a strong, skilled workforce.

- A good source of electronic components relating to automobiles, such as PCB boards, basic chips, etc.

- A high quality of labor, with a strong work ethic, skilled in industrial, appliances, and automotives. Only difficulty can be with availability, and this is where having someone local who can help sourcing can assist.

Client Case Study #3

Moving Operations to Thailand, Clients in Southeast Asia

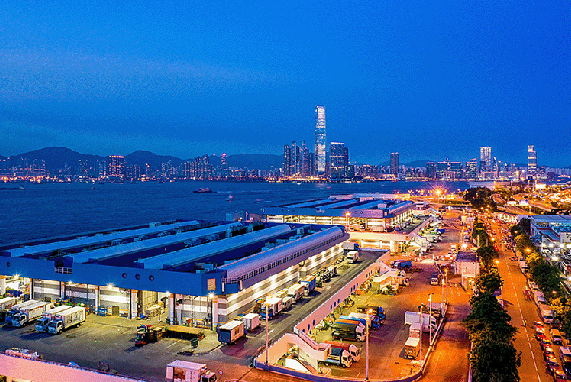

Our last example was a very large iconic manufacturer of electronic equipment selling into industrial markets and was established in China since the early 2000s in Guangdong Province, with growth of their markets in ASEAN.

We were asked to do a study to find a larger facility close to their current one so they would be able to keep their labor force. We demonstrated to them it would be better for their market base if we broadened it to ASEAN to keep their facilities on the cutting-edge, looking at Vietnam, Thailand, and Malaysia.

After negotiating with Thailand’s Board of Investment, we brought our client’s second design center which included their R&D first tier products and the internet of things connected products to Thailand, and the Thai government gave them a 10-year corporate tax holiday and 5 more years at a 50% tax. This saved the company an enormous amount of money compared to if they built a new facility in China.

Currently, in Southeast Asia, we find:

-

- Their productivity levels and R&D are equal to those you would find in China with half the labor rates for manufacturing.

- Your IP is much more protected, and you don’t have to worry about the government of where you are dealing with to try to compete with you.

- There is still the Treaty of Amity that goes back 150 years where there are no duties, so if your content is over 60% coming back to the US is zero duties from Vietnam.

Helpful Tips

For Closing a Plant or Operation Center

When you are going to close a production center in China, you need to anticipate the time involved and put together a solid, upfront plan.

Set aside a two-month period working with corporate management and local leadership to develop solid plans around:

- Understanding required severance

- Understanding market practices around severance

- Communication plans

- Inventory disposition

- Whether you need to build up or draw down inventory.

The need for a multifunctional or cross-functional planning is key for a successful plant closing.

For assistance with a plant closing or if you have additional questions, please call or contact us at 704.807.9531 or abryant@eastwestassoc.com.

Timely Topics To Drive Growth.

Sign up for our webinars.

Sign Up